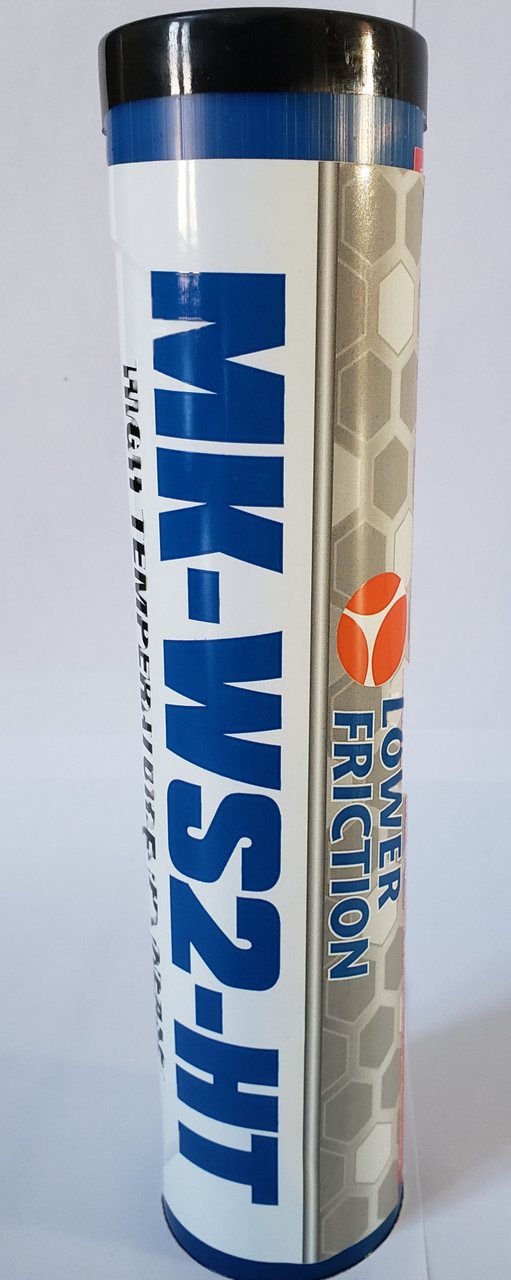

The Functional Specifications and Qualitative Features of WS2 Grease

WS2 Grease | cdn11.bigcommerce.com

Tungsten Disulfide the other name for which is WS2 is a kind of low-friction dry lubricant. It is something to help improve the performance and service level of the metal coating. It is not like the dry lubricant and can help reduce the level of noise and friction. It can cause improvement in the mold-releasing process and solve issues of extreme wear, galling, seizing, and even the occurrence of fretting. It is a kind of Tungsten Disulfide coating and the process is done with the help of pressurized air. This can cause impinging of the dry metallic coating without the use of binders, heat, or adhesive.

Qualitative Usage of WS2 Grease

The use of WS2 Grease is imperative. This kind of lubricant coating can cause an instant bonding with any metal or resin substrate and has the desired thickness as par functionality. It has a low-friction coating that can both reduce and overcome mechanical lubrication issues. This can help improve the level of performance and the extended life service. The lubricant coating can help reduce the friction level and as there is less emission there is reduced fuel usage for the destined power level. This happens when things are applied to various engine parts like cams, piston rings, and bores.

More Traits of the Lubricant Coating

The use of the specific lubricant coating will help in eliminating and reducing costly maintenance issues. This can lead to breakdowns and expensive downtime which can stop occurrences of fretting, galling, and friction. This is caused by separate metals and their various hardness traits. Tungsten Disulfide will help in maintaining the kind of dimensional integrity of the specific substrate within the measurement of 1/2 microns. Here the thickness of the coating matters. This is something that helps protect the surface and makes things easy to round.

Qualitative Traits of the Grease

The qualitative WS2 Grease can easily withstand a load of an amount of 100,000 psi. It is the load capacity that is equal to the substrate. Things can operate within the temperature range and this is the range between -460°F to 1200°F (-273°C to 650°C). The kind of grease will offer 100% lubricity throughout the texture and make things better malleable. This is how the lubricant works and makes things proper and in shape. The grease is non-toxic and it is both inert and inorganic. The grease is resistant to most fuel-type solvents. Here things are highly compatible and this in turn will help in enhancing the performance of the grease and the oil.

The nature of Tungsten Disulfide is such that it can molecularly bond all the materials and the platings. Things can be eliminated with the removal of the bonded substrate. The application of Tungsten Disulfide is straight and there is no heat curing or bake-out involved in the process.